Avoiding Costly Catastrophes

Avoiding Costly Catastrophes

Lift stations are key assets for wastewater utilities. Their functionality is essential for operation in almost any collection system. Therefore, it is important for utilities to be able to monitor the health of each remote site.

Existing monitoring solutions often provide very limited visibility of the sites condition. For example, monitoring pump runtimes and being alerted if the level is too high or a pump fails. This limits the ability for the utility to simply establish a preventive maintenance schedule or get key insights to their system performance and asset health.

Modern IoT (Internet of Things) technology made edge computing more powerful and affordable. As a result, analytics that previously required additional or specialized hardware can now be performed more efficiently. Whereas last generation hardware was limited in processing and connectivity that resulted in delayed low resolution data transfers, modern hardware can deliver key features like these:

· Detect problematic pump AMP draw conditions

· Calculate pump flow rate & inflow rate based on a model (without the need for a flow meter)

· On-edge pump cycle counting, runtime aggregation and flow totalization

· Frequent real-time data transfer schedules and smart on-change data transfer

Practical Example: understanding the route cause of problems by increased data transparency

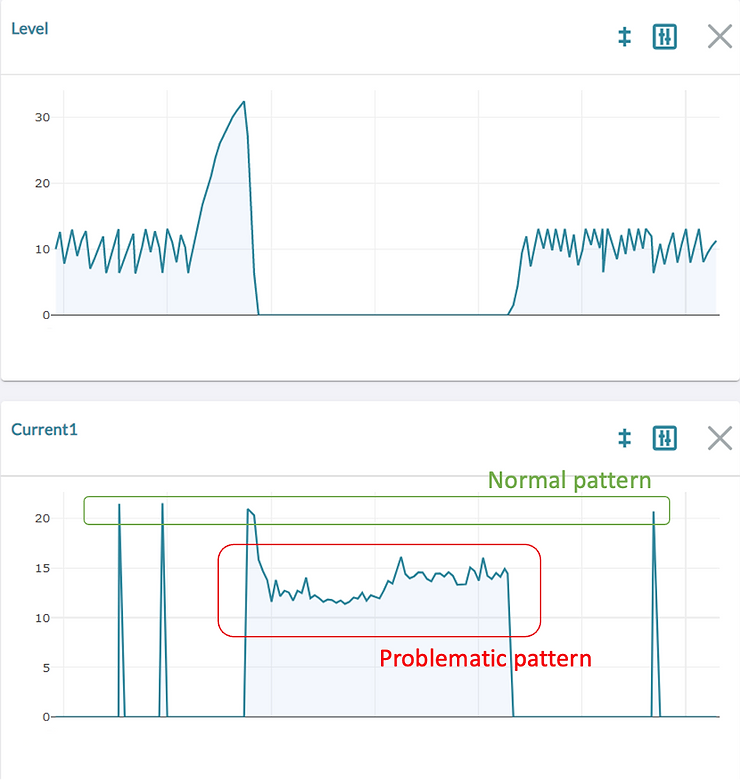

Furthermore, the root cause of the high-level condition could be detected by overlaying the pump run information with the well level data. It can be concluded that there is a problem with an electrical part in the pump control cabin.

Like other industries the water and wastewater industry will face the challenge of an increased lack of qualified professionals.

Latest technologies, like hardware with more powerful processing power, internet of things (IoT) and analytics will play an increased role in filling this gap. It will enable professionals to be more efficient with their time and makes problems visible before they lead to emergencies. Additionally, an application of modern software will increase the attractiveness of jobs for the next generation of professionals.

Better Software, Stronger Performance, Overall Improvement

In an industry where time is money, having software that provides data in an efficient manner can help professionals save time and money. Currently, the software used is borrowed from other industries, leaving gaps within the industry. With the water industry being pushed to the sidelines, it is no surprise that software in the industry lacks the ability to provide information in an efficient manner. Although many companies do provide solutions that are often transferred (with some difficulty) to the water and wastewater industries, there is generic software initially offered that is designed specifically for other industries such a soil and gas, energy, construction, etc.

The importance of having software designed specifically for your water processing equipment could potentially save you thousands of dollars along with time and overall energy, especially with the numerous remote sites integral to most municipal water processing systems. Physically inspecting pumping stations and other remote or underground sites leads to challenges with efficiency and productivity. Replacements are costly and if neglected can lead to uncontrolled overflow of wastewater and leave lasting damage to the environment and community. For example, emergency replacement of a faulty lift station pump can cost between $50,000-$75,000.

When looking at what is needed to create successful software for the industry there are three main elements that need to be incorporated. The three pillars that are needed to be kept in mind in order to create software specifically for the water and wastewater industries. First and foremost, the software should be developed with the sole purpose of being for the use of water professionals. The current path of the software being developed by programmers who don’t have experience in the industry is no longer working and it is crucial to the effectiveness of the software to be created by individuals who have firsthand knowledge of the industry.

The next pillar to ensure success is making sure there is a platform that helps both water managers and water operators in doing their job. The software also needs to connect disparate systems to support employees instead of adding tasks. This also allows professionals to access information about the pipes without having to physically be there. With the evolvment in technology, it is crucial for the industry to embrace the benefits rather than being hesitant about it.

Lastly, it is important to make sure there is software that allows the linking of data across the catchment and utility teams. With multiple different teams being able to access all the data, it allows for everyone to be on the same page. By linking the data there is more cohesion within the company along, especially with different departments.

By having all of the data information in a centralized place over a field spot check, it saves labor and time. There is also a benefit in that there are warnings before a problem arises and you get notified through notifications, alerts, and alarms. This can include anything from increase flows, pressure, and current (electrical) fluctuations, filter and membrane clogs, power losses, and other equipment issues or failures.

STREAMETRIC Remote, the newest addition to the STREAMETRIC platform developed specifically for the water industry allows professionals to have all the data needed to stay updated with the status and health of each remote lift station, pump, water tower, underground tank and other remote operations without having to physically do inspections and before costly damage occurs. With the predictive maintenance that our software provides, you are able to follow maintenance intervals and set alarms for problematic conditions.

Interested in saving time and money? Click here to speak to one of our experts about what STREAMETRIC can do for you.

Wastewater and Beers? The Innovation of Water Reuse

With our largest natural resource, water, slowing dwindling down due to supply and demand, it has become a necessity to learn how to reuse wastewater. There have been many ways companies have learned to reuse wastewater, whether it is being cleaned for drinking water or even new applications like brewing. Even though the Earth is made up of 70% water, only 2.5% is fresh water. Of that, only .007% of the fresh water is easily accessible, the rest being trapped in glaciers and snowfields.

Turning wastewater into drinking water is something that many regions that lack the resources have had to resort to. Orange County in California, for example, has been deriving drinking water from sewage since the 1970’s and now stands as an example of political conservatism for the rest of the country. With the planned expansion of their water-plant in 2023, it is expected to generate 130-million-gallons of drinking water.

Another way wastewater is being re-used is through crafting beer. Yes, you can now crack open a cold one that is made from recycled sewer water! The challenge posed with this new beverage application is overcoming the psychological and cultural challenges consumers have drinking beer with the knowledge it was once wastewater. There are a variety of different types of beer including pilsners, IPA’s, and pale ale’s, giving every beer drinker the opportunity to try their favorites!

The United States government is also beginning to recognize how pressing this problem is and is encouraging more research in water technology. The Department of Defense awarded a $3.8 million grant to Marquette University in which they found and developed a high-performance catalyst that can pull ammonia from nitrates in wastewater that results in clean water.

A new Stanford study has paved the way for mining sewage to draw out and reuse materials usually used in fertilizer and batteries for potential use in phone and airplane components. This groundbreaking research will lead to wastewater having multiple reuses that can help benefit multiple industries in the near future.

With STREAMETRIC, our technology helps maximize the water plants' performance and reduce downtime. Looking for more information? Check out our website https://www.streametric.io/about-us

Sewage Overflow- A Problem for Today

Managing overflows in sewers should never be overlooked due to the amount of damage that can occur from it. The EPA estimates that 549,490,887 gallons of raw sewage was released in 2021. This type of sewage overflow leads to public health threats, financial damage, environmental damage, and months of costly clean up. Understanding underlying causes of sewer overflow and how new technologies can help prevent them will save your water treatment operations tremendous amounts of time and money.

The number one purpose of above ground sewer systems is to contain the wastewater that flows into them but there are factors that can overwhelm the system and lead to overflow — something that our technology is able to minimize. Too much rainfall or snowmelt, pipe failures, and grease and oil buildup all contribute to systems failing and lead to overflows.

Once these overflows occur, it can be hard to contain, and the force of the rushing water can be extremely powerful.

Real life occurrences of overflows happen more often than we even realize. In 2020 Henderson County, North Carolina experienced 3 dozen sewer overflows after 12 hours of heavy rainfall. This led to the roads being flooded and enough water to lift construction barrels. The day after the rainfall, more than 5 thousand gallons of water waste flowed through the county.

Armed with the right knowledge BEFORE an incident improves the chance of avoiding overflow. Technology that converts data collection into actionable insight allows system operators to prepare in advance for potential upticks in flows. Monitoring technology that includes not only system overviews of pump flows and pressure but also ties into weather tracking takes data to the next level with predictive capabilities.

Wastewater pump stations can easily be retrofitted with a sensor box that feeds directly into a monitoring platform for substantially lower cost than a cleanup after the fact. This is the first step in taking precautions prior to a catastrophic sewage event happening. Additionally, monitoring solutions allow for improvement of the system's reliability, reduction in costly process additives like chemicals and aeration needs and can predict potential failures across the entire wastewater treatment system.

Learn more about avoiding sewage overflows and reducing operational costs from a STREAMETRIC wastewater expert today.

Ready to see how live? Take a tour of the latest technology.

Membranes are Meaningless Without Monitoring

Membrane technology has come a long way. Membranes remain a critical part of water operations. So much so that if membranes don’t perform, then the plant comes to a standstill with planned downtime. The equipment can be very costly to repair, or even more serious, replace in some cases. Taking care of your investment ensures you can get the most out of your system.

What good are membranes if you don’t keep up with maintenance? That might be a no-brainer, but how often do you run checks on your equipment? If it’s less than hourly, you may be missing valuable information regarding your operation, putting your membranes at risk.

Issues that come with membrane systems like pre-treatment filter failure, change in feed water quality, higher inflow/long peak flow, leaks and reduced concentration due to chemical age can be prevented with the right data and insights to know what to do with it. Whether preventing fouling or scheduling cleanings at the right time, having a monitoring system in place is crucial to maintain efficiency. Many systems do not have sufficient instrumentation to check all the parameters that must be monitored to catch problems at an early stage when they can still be reversed. Even if the instrumentation is adequate, many facilities do not trend the data, or even worse, no one looks at the data at all.

The most common issue with membranes is fouling — where deposited materials collect along the membrane surface — reducing its efficiency and increasing energy usage. When fouling inevitably occurs, it can be a tough problem to deal with because the damage is often irreversible. However, membrane monitoring affords early detection and an opportunity to address it before becoming disruptive to operations. For example, when see a spike in transmembrane pressure (TMP) in the trendline, you will be able to schedule the best time for membrane cleanings, resulting the least disruption to production. Simple fixes, such as graphing system pressure after cleaning, can extend the life of your membrane by showing the effectiveness of said cleanings. With fouling, the best defense is a good offense.

To extend the life of your membranes, a monitoring system can detect factors that cause problems for the membrane itself such as a pre-treatment failure. Monitoring systems track differential pressure and create alarms for when it approaches unsafe conditions. If there is a change in feed water quality, this too can be directly monitored through turbidity PH and conductivity. Or indirectly through tracking the fouling rate of the membrane since an increase in this rate indicates problematic feed water conditions.

When cleaning your system, how do you know your cleaning was effective? Monitoring solutions have evolved and now predict data that we have previously not been able to accurately anticipate. With today’s monitoring solutions, you can easily see that data trend on a chart. Even better, you can use this data to your advantage and schedule cleanings at the most effective time. By combining weather data into AI monitoring software, predictions in permeability and TMP are automatically made so you can even make plans for when the circumstances are outside of your control.

The proactive approach recommends a conditions-based plan over a time-based one to preserve your membranes because you do not want to go overboard with time-consuming, costly cleanings. By trending your data before and after cleaning, maintenance scheduling becomes predictive, resulting in less downtime and more efficiency within the system overall.

Want to learn more about water membrane monitoring? STREAMETRIC is a monitoring solution powered by machine learning analytics. Contact a STREAMETRIC water management expert today.

Infrastructure Bill Pours $55 Billion into Water

When you hear infrastructure, your first thought is probably roads and bridges. But, water is part of that equation... a fairly substantial part of that equation really. Of the $550 billion in new spending, $55 billion is dedicated to drinking water, wastewater and stormwater infrastructure funding.

Getting contaminants out of the water

Much of the funding has been allotted towards eliminating contaminants in our water supply, as well as replacing lead pipes to prevent another disaster like Flint Michigan. This is a major change for the water industry intended to make clean water more reliably accessible to American families everywhere in the country regardless of location, income level, or other factors. Currently, 10 million American households and 400,000 schools and childcare centers lack access to clean drinking water. Per the White House fact sheet, “the legislation will invest in water infrastructure and eliminate lead service pipes, including in Tribal Nations and disadvantaged communities that need it most.”

PFAS are another major water contaminants focus of the Bill. PFAS stands for perfluoroalkyl or polyfluoroalkyl substances. Under the PFAS group of chemicals, you have PFOA (think chemical coatings like Teflon) and PFOS (an ingredient used in most fabric protectants). The plan is to tackle PFAS by 2024 as shown in this roadmap released from the Biden administration.

Plus, cleaner water into the system translates to less processing for use in production saving time and money for companies across a variety of industries.

What This Means for Water Treatment Facilities

So, how will the $55 billion earmarked for the water industry disperse? According to Waters & Wastes Digest, the intended breakdowns in funding are as follows:

Drinking Water

- $11.7 billion over five years for the Drinking Water State Revolving Fund

- The Alternative Source Water Pilot Program will get $125 million over the next five years

- $4 billion will be provided in grants through the Drinking Water SRF to address PFAS in drinking water

- $15 billion in loans and grants into Drinking Water SRF for lead service line replacement for municipalities

Clean Water

- $11.7 billion over five years for the Clean Water State Revolving Fund (SRF)

- The Wastewater Energy Efficiency Grant Pilot Program will receive $100 million over the next five years

- $1 billion through the Clean Water State Revolving Fund to address emerging contaminants

- Decentralized Households grants will get $150 million over five years to help low-income homeowners construct or repair failing septic systems

Stormwater

- The U.S. EPA Sewer Overflow & Stormwater Reuse Municipal Grant Program will receive $1.4 billion over the next five years

- The Stormwater Infrastructure Technology Program will get $25 million to create five Stormwater Centers of Excellence

- $50 million for stormwater infrastructure planning/development and implementation grants

- EPA will get $5 million per year to complete the Clean Watershed Needs Survey biennially

Got question? Want to learn more about this topic? Our water industry experts are here to help at info@streametric.io

How STREAMETRIC Helped M|MBR Save Thousands of Hours in Remote Monitoring

Recently, we spoke with the leadership team at M|MBR, our membrane partner in Austin, Texas. They specialize in the delivery, service, and support of existing and new MBR systems. Watch our case study video to learn how STREAMETRIC has helped M|MBR save hundreds of hours, reduce downtime, and improve remote monitoring.

Take Back 2000 Hours of your Time

How advances in remote monitoring create new efficiencies annually.

Data collection, interpretation, and reporting are the daily responsibilities of operators, managers, and service engineers of water and wastewater treatment plants. The tools available to them require lots of manual work, leading to enormous amounts of time being spent. Manual collection of data can result in gaps where data is missing, further complicating accuracy. With advances in remote monitoring, data reporting is now done automatically and stored for long-term trend analysis. This allows operators and technicians to spend time elsewhere often increasing productivity and overall efficiency.

How Customers Benefit from STREAMETRIC

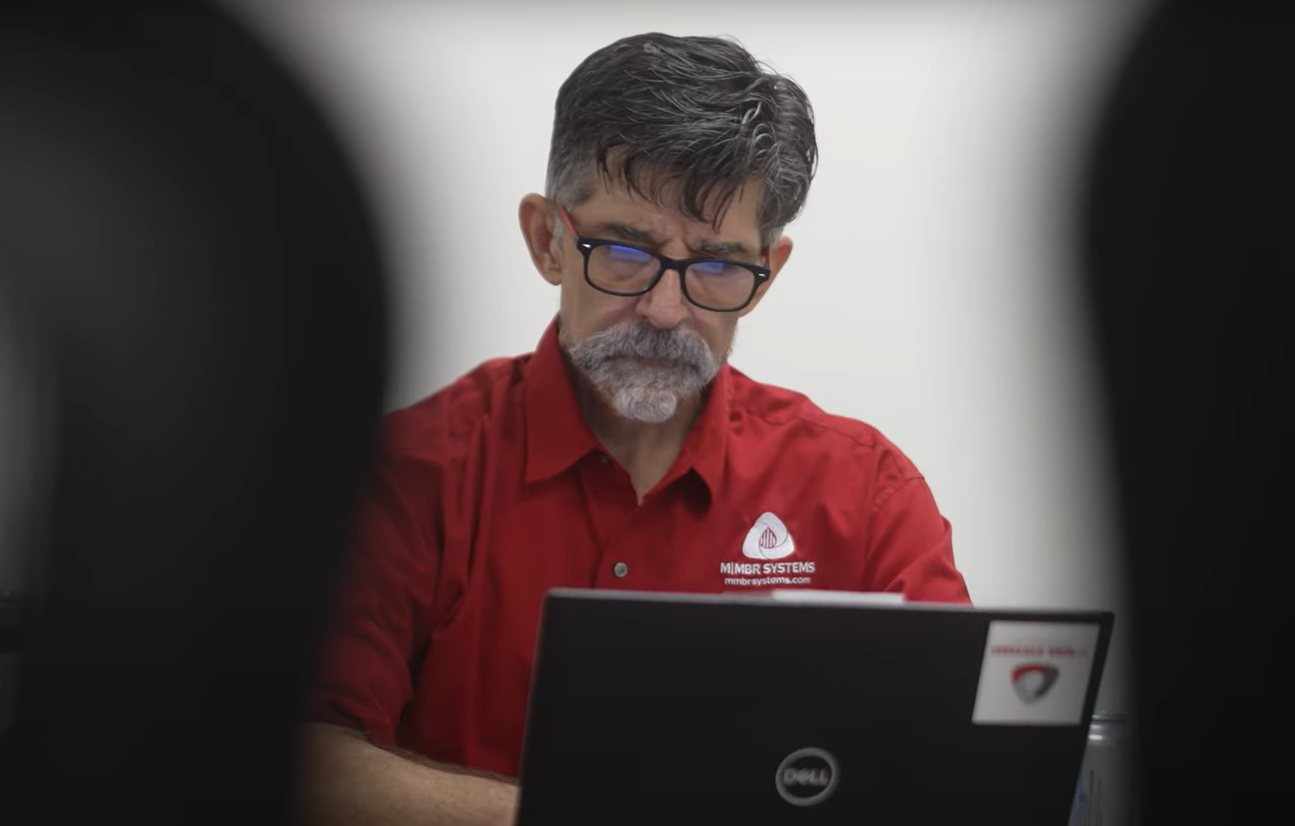

With the enormous amount of data generated in today’s water plants, there is a star comparison between the previous way of collecting data and the new tools for remote monitoring. We spoke with Mark Parli, Technical Service Director at MMBR Systems. Over a single period of a support contract for a large wastewater treatment plant in Texas, he was involved in creating over 92 spreadsheets to track the plant’s performance and support maintenance decisions. He noted: “We were probably putting in 20 hours a piece on each of these spreadsheets. That is a lot of hours to get the same sort of impact that I’m getting out of those 92 spreadsheets. It takes me 20 minutes with STREAMETRIC.”

Monitor Your Plants from Virtually Anywhere

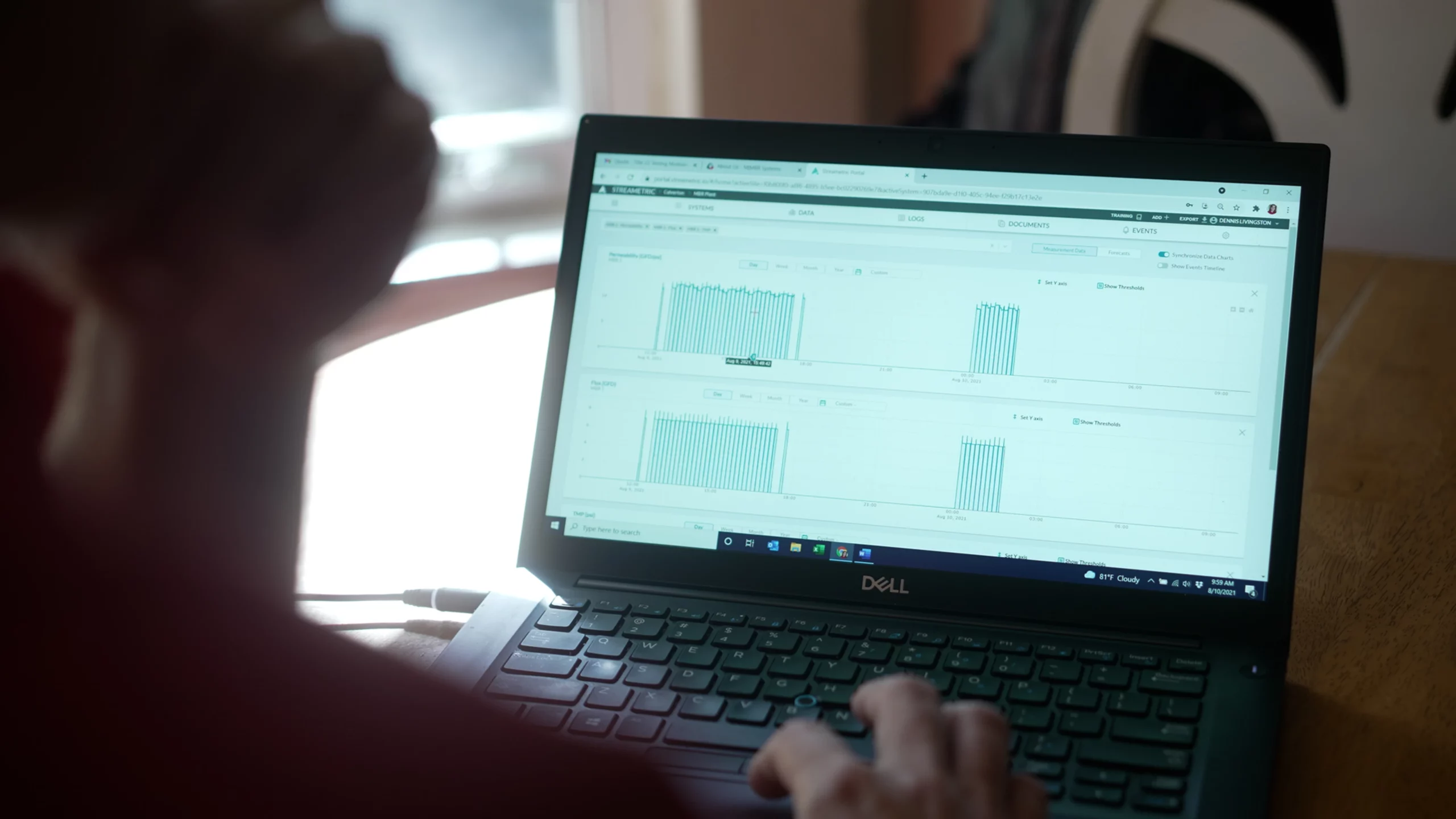

The cost of traveling to different locations to check the status of plants will certainly accumulate over time. With more advanced monitoring software, you are able to check reports from the office, at home over breakfast to better plan your day… or, virtually from anywhere via mobile device. Technical Director of MMBR Systems, Dennis Livingston, noted that remote monitoring dashboards add a more holistic overview of systems across multiple locations simultaneously. “We may be monitoring a dozen different plants, and I can see the key parameters for each plant in a snapshot.” Remote monitoring’s quick and easy tools give systems managers access to the key parameters, synchronized data, overlap event logs, and a simpler view of where obstacles are occurring and what is causing an issue. Having access to this data allows one to have specific solutions to pending issues.”

Trends, Events, and Offline Data in One Place

New monitoring software offers a complete data package that you are unable to get with just spreadsheets. You can also map trends along with the logged events. From here, events can be overlayed onto the trends, which allows for users to have the complete data package experience. A varied range of information is available and able to be transformed into actionable solutions and results. This streamlines the complex process of reporting.

Finding experienced talent is also a main challenge of the water and wastewater industry today. A modern monitoring solution like STREAMETRIC doesn’t just save lots of time, it also helps to retain young professionals. The cutting-edge technology attracts those involved with machine learning, AI, and much more.

The Future is Predictive Analytics

Adding predictive analytics to remote monitoring empowers data-driven decision-making that helps your water filtration technology reach its full potential. STREAMETRIC combines 70 years of filtration expertise with machine learning to empower you to make prediction-based decisions for your assets. Our state-of-the-art technology allows us to build predictions capabilities customized for your application in less than a month. STREAMETRIC allows for its users to maintain their assets’ performance long term and to improve their cost-efficiency. It is STREAMETRIC’s vision to improve the sustainability of filtration.

Ready to Improve Your Remote Monitoring?

Contact STREAMETRIC for more information.

Watch our M|MBR Case Study to Learn More.

Service 4.0 - How System Integrators benefit from Online Data Monitoring

M|MBR is a leading system integrator and service provider for MBR systems in North America. The company started using STREAMETRIC in 2019. In the following testimonial Dennis Livingston, Technical Director of M|MBR, shares how the STREAMETRIC platform enables his team to pro-actively support their clients.

Testimonial

Testimonial

"My teams have helped to deliver nearly 300 membrane bioreactor (MBR) systems over the last two decades ranging in size from 5,000 gallons per day (gpd) to 42,000,000 gpd. In that time, we have used a variety of remote monitoring tools, including dial-up access to programmable logic computers (PLCs) and different supervisory, control and data acquisition (SCADA) systems. One of the best platforms for monitoring and optimizing MBR performance is, without a doubt, STREAMETRIC.

First and foremost, STREAMETRIC is easy to use, whether you are supporting one or multiple plants. Our team monitors the status of numerous installations from one coast to the other. Being able to setup personalized dashboards makes tracking performance at all these sites manageable. But the ability to quickly overlap critical data and to navigate through enormous amounts of online information is what makes the tool so useful.

Without STREAMETRIC, analyzing and comparing key parameters like permeate flow, flux, and permeability can take hours. With the STREAMETRIC “sync” function, and now with Event Log charts, performance evaluations can take minutes. Syncing multiple parameters, and changing time slices, allows us to quantify performance and understand the meaning of trends better. With a few clicks, we can look at a 1-hr window of operation, back out to look at the last 30 days for context, and then go back to our 1-hr time slice for assessment. If needed, we can drill down even further to create meaningful trends that support clear recommendations.

"M|MBR uses STREAMETRIC to help our operators prevent problems and optimize their plants' performance. Examples of the type of support made possible with STREAMETRIC include membrane cleaning adjustments, coagulant dosing optimization for phosphorus removal, and improving ammonia removal as a function of air scour. In addition, to system performance optimization, our team is able send out weekly advice to operators based on concise, clear reports. Those reports, coupled with periodic equipment inspections, keep operators up to speed about how their equipment is performing compared to plant-specific metrics and relative to industry expectations.

STREAMETRIC is one of the best data monitoring platforms available for supporting MBR systems. Operators can use it as a cost-effective, easy way to stay on top of their systems and or team up with our experts through customized service plans. Whichever direction customers go, having predictive analytics and clear performance data at your fingertips is the best way to operate an MBR system. We highly recommend STREAMETRIC for any MBR system."

Dennis Livingston, Technical Director, P.E.

M|MBR Systems

Elevate your Pilot Projects with STREAMETRIC

The importance of pilot plants

Pilot plants aren't often thought of as pivotal in driving technology, but they provide the perfect environment for researchers and developers to test products under critical conditions. Pilot plants also empower growth by providing an arena for sales teams to display product feasibility and efficiency to customers, using real-life scenarios. It isn't uncommon to find that manufacturers, Universities, and municipal or industrial end-users all collaborate in pilot projects because of its many uses.

Avoidable Obstacles

Direct access to reliable operational data can be a significant challenge for all parties throughout a pilot project, and unfortunately, pilot and trial success depends on that accessibility. The project run by MICRODYN-NADIR and the Darmstadt University of Applied Sciences provides a perfect example of this challenge. Currently, they are operating a pilot plant with the BIO-CEL® Activated Carbon Process at a wastewater treatment plant in Germany.

Due to the considerable spatial distance, continuous plant monitoring was impossible without the significant support of the sewage personnel. Data had to be regularly exported through the onsite PLC control panel to a USB stick and manually analyzed in Excel. The results weren't shared with the project participants until days later, in an email.

This approach was not only labor-intensive, but it also led to data loss risks and delayed detection of process issues, such as changed operation conditions, system downtime, and increased membrane fouling.

The STREAMETRIC Advantage

Installing STREAMETRIC was a game-changer for this project's success. Participants used our digital features to monitor the pilot plant's operating parameters online securely. STREAMETRIC was directly responsible for removing the need for frequent onsite visits by University personnel and the help by the sewage plant personnel, which provided much-needed flexibility and aided overall cost reduction.

Installing STREAMETRIC was a game-changer for this project's success. Participants used our digital features to monitor the pilot plant's operating parameters online securely. STREAMETRIC was directly responsible for removing the need for frequent onsite visits by University personnel and the help by the sewage plant personnel, which provided much-needed flexibility and aided overall cost reduction.

The STREAMETRIC advantage doesn't stop at tactfulness and cost savings; our technology simplifies the optimization of the membrane's cleaning strategy. Each cleanings' effect is tracked and evaluated in real-time, leading to improved working hours while increasing reliability. Since trusting STREAMETRIC with its pilot project, the team hasn't experienced any system failures.

Please don't take it from us; see what Maximilian Werner, the R&D Lead for the BIO-CEL® Activated Carbon Process at MICRODYN-NADIR, has to say about STREAMETRIC. "The simplicity of combining data from different parameters, monitoring different historical time frames, and tracking membrane cleanings has changed the way we look at data. Previously, we had to wait for the raw data to be exported and analyzed. Now, we see the impact of our operation related decisions on all parameters in real-time. STREAMETRIC allows us to make quick decisions and is an enormous increase in flexibility."

Contact us at info@streametric.io to learn what STREAMETRIC can do for you.