Avoiding Costly Catastrophes

Lift stations are key assets for wastewater utilities. Their functionality is essential for operation in almost any collection system. Therefore, it is important for utilities to be able to monitor the health of each remote site.

Existing monitoring solutions often provide very limited visibility of the sites condition. For example, monitoring pump runtimes and being alerted if the level is too high or a pump fails. This limits the ability for the utility to simply establish a preventive maintenance schedule or get key insights to their system performance and asset health.

Modern IoT (Internet of Things) technology made edge computing more powerful and affordable. As a result, analytics that previously required additional or specialized hardware can now be performed more efficiently. Whereas last generation hardware was limited in processing and connectivity that resulted in delayed low resolution data transfers, modern hardware can deliver key features like these:

· Detect problematic pump AMP draw conditions

· Calculate pump flow rate & inflow rate based on a model (without the need for a flow meter)

· On-edge pump cycle counting, runtime aggregation and flow totalization

· Frequent real-time data transfer schedules and smart on-change data transfer

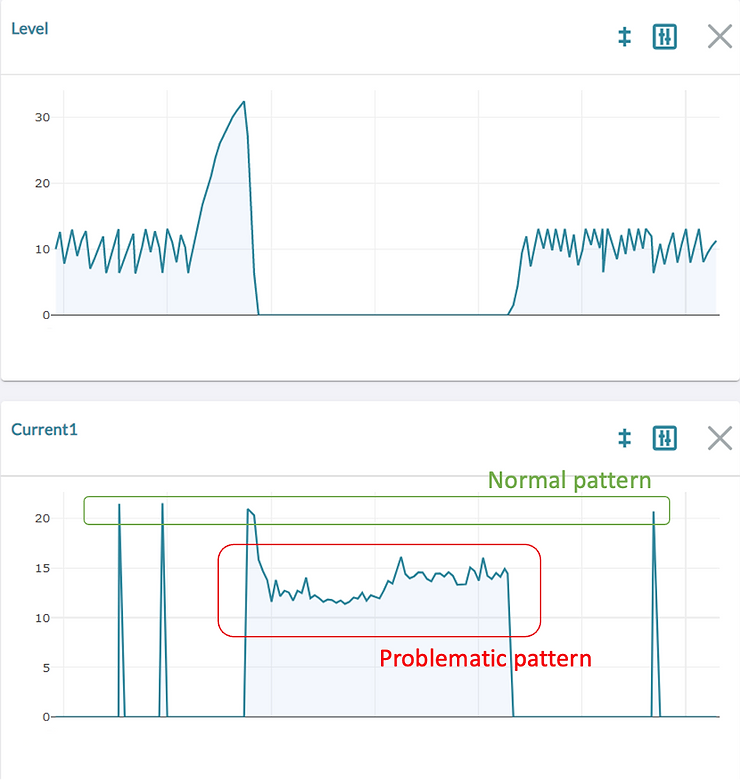

Practical Example: understanding the route cause of problems by increased data transparency

Furthermore, the root cause of the high-level condition could be detected by overlaying the pump run information with the well level data. It can be concluded that there is a problem with an electrical part in the pump control cabin.

Like other industries the water and wastewater industry will face the challenge of an increased lack of qualified professionals.

Latest technologies, like hardware with more powerful processing power, internet of things (IoT) and analytics will play an increased role in filling this gap. It will enable professionals to be more efficient with their time and makes problems visible before they lead to emergencies. Additionally, an application of modern software will increase the attractiveness of jobs for the next generation of professionals.